Fisher Snow Plow Harness with Molded Plug Fit Nickel Plated Terminal and 1 Year Warranty for Vehicle Control Wiring

Dettagli:

| Luogo di origine: | Guangdong, Cina |

| Marca: | Edgar wireharness & EdgarWireHarness |

| Certificazione: | ISO 9001:2008 / UL /IPC620 / IATF16949 |

| Numero di modello: | cablaggio di controllo del veicolo |

Termini di pagamento e spedizione:

| Quantità di ordine minimo: | 10000 |

|---|---|

| Prezzo: | $1.66-1.88 |

|

Informazioni dettagliate |

|||

| Tipo di cavo: | cablaggio di controllo del veicolo | Tipo di filo: | Stampa GXL |

|---|---|---|---|

| Tipo di terminale: | Delphi | Trattamento superficiale: | Nichelato |

| Materiale del nucleo di filo: | Filo di rame | Materiali per le bende: | Pipe in PVC |

| Spec: | TXL12AWG, 16AWG | Marchio connettore: | Delphi originale |

| Metodo di marcatura: | Stampa di contenuto personalizzata sul filo | Protezione del cavo: | Intrecciato coperto |

| Protezione dei connettori: | Cap del culo | MATERIALI PIN: | Nichelato |

| Modello n.: | WH-GG-1001 | Tipo di industria: | Arnesi di cablaggio per autoveicoli |

| Classe di assemblea: | Stampaggio a iniezione | ||

| Evidenziare: | 1 Year Warranty Automotive Wiring Harness,Molded Plug Fit Vehicle Control Wiring Harness,Nickel Plated Terminal Truck Headlamp Wire Assembly |

||

Descrizione di prodotto

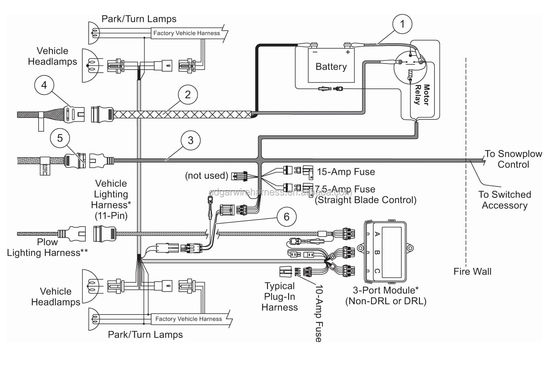

This vehicle control wiring harness is designed for Fisher snow plows with molded plug fit compatibility for Douglas Dynamics systems. The harness features Grote lights compatibility and is built for reliable performance in demanding winter conditions.

| Model No. | WH-GR-1001 |

|---|---|

| Application | Automobile, Headlamp (H9, H11) |

| Wire Core Material | Copper Wire |

| Industry Type | Automotive Wiring Harness |

| Bandaging Materials | PVC Pipe |

| Certification | SGS, ROHS, ISO9001, UL |

| Auto Wire Spec | TXL12AWG, 16AWG |

| Connector Brand | Original Delphi |

- 100% brand new and high quality construction

- High sensitivity and easy to control

- Perfectly suitable and easy to install

- Organized wire connections

- 1 harness per protective bag

- 1 year warranty included

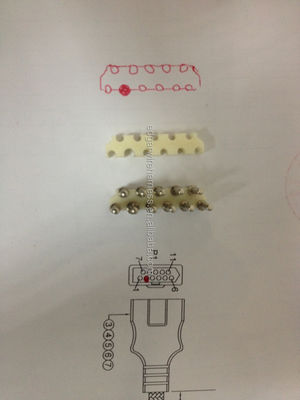

This wire assembly is specifically designed for truck headlamps, customized for GROTE US applications. The automotive wire assembly can be marked with customer-required content and includes special braiding protection for the wires. To prevent deformation during shipment, we include protective caps for the molded connectors.

Our manufacturing process follows a professional flow chart including wire cutting, stripping, copper twisting, crimping, 100% inspection, soldering, molding, assembling, braiding, testing, and final quality control to ensure stable product quality.

We offer professional project management and part design/modification services, including:

- Customized wire harness solutions with backup accessories

- Worldwide export via FOB or customer-specified shipping methods

- Quality assurance through IATF16949 & ISO9001 quality management systems

- UL E468011 & UL E468011 certified production

Packaging details can be customized to client specifications. Standard lead times:

| Quantity (PCS) | 1 - 1000 | 1001 - 5000 | >5000 | Mold/Tooling |

|---|---|---|---|---|

| Est. Time (Days) | 20 | 25 | To be negotiated | 30 days more |

International shipping available via DHL, UPS, FedEx, TNT, ARAMEX and EMS. Customers may choose air, sea or other shipping methods.